Why Use Railway Gauge Baffle Plates?

Nov 10, 2025

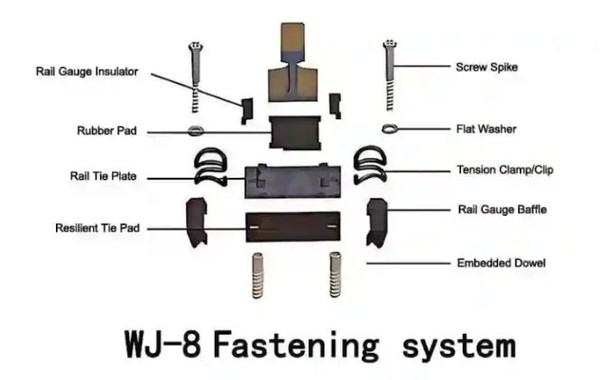

Railway Gauge Baffle Plates are key components of the railway fastener system, with their core value lying in ensuring track stability and train operation safety. They are indispensable supporting products for core fasteners in modern railway engineering.

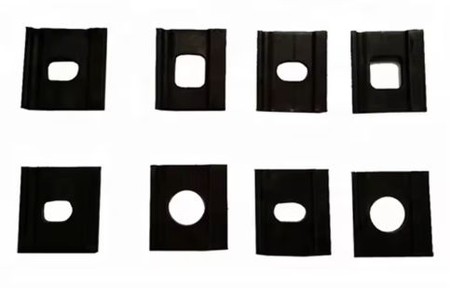

Precisely Control Gauge and Lock Track Geometric Dimensions

Gauge is a fundamental indicator of track safety. By cooperating synergistically with elastic rail clips and sleeper bolts, this component can accurately fix the spacing between two rails (standard gauge: 1435mm) and prevent lateral displacement of rails during train operation. Different models (6#, 10#, 14#, etc.) are compatible with various fastener systems such as Type Ⅰ and Type Ⅱ. Combined with design of different hole types including slotted holes and square holes, it can flexibly adjust installation errors, ensuring that the gauge remains within the standard range for a long time.

| Railway Rail Guide Plates | Hole | |

| Type-II Railway Fastening System | 6# | Oblong hole |

| Type-II Railway Fastening System | 10# | Oblong hole |

| Type-II Railway Fastening System | 6#, 10# | Square hole |

| Type-II Railway Fastening System | 3# | Square hole |

| Type-I Railway Fastening System | 13# | Big round hole |

| Type-I Railway Fastening System | 14#, 20# | Oblong hole |

| Type-I Railway Fastening System | 14#, 20# | Big round hole |

| Type-VI Railway Fastening System | 12#, 16#, 20#, 24# | Oblong hole |

| Type-III Railway Fastening System | 6# | Square hole |

| Type-III Railway Fastening System | 10# | Square hole |

Transmit and Disperse Loads to Protect Track Components

The transverse impact force generated during train operation is transmitted to the gauge baffle plates through the rails. Made of high-strength materials such as Q235 and 65Mn (tensile strength ≥ 370-500MPa), they can effectively disperse loads, avoiding damage to rails and sleepers caused by local stress concentration. Meanwhile, they can buffer vibrations, reduce wear of components such as elastic rail clips and railway plastic dowels, and extend the service life of the entire track system.

| WJ-8 Rail Fastening System Parts Details | |||||

| Serial number | Name | Quantity | Material | Mass or volume | Remarks |

| 1 | Spiral spike | 2 | High quality carbon steel or alloy steel | 1.50kg | The S2 type is generally used, and the S3 type is used when the height is greater than 15 mm. |

| 2 | Flat Washers | 2 | Q235-A | 0.138kg | |

| 3 | W1 type elastic clip | 2 | 60Si2MnA | 1.44kg | The general section adopts the W1 type, the single elastic rail clip buckle pressure is greater than 9kN, and the elastic stroke is 14mm. |

| X2 type elastic clip | 1.28 kg | The X2 type is used for the small resistance area. The single spring buckle has a pressure of 6kN and a stroke of 12mm. | |||

| 4 | WJ8 insulation block | 2 | Glass fiber reinforced nylon PA66 | 79.0cm3 | Type I, used in general locations. |

| 73.0cm3 | Type II, used at rail joints. | ||||

| 5 | WJ8 gauge baffle | 2 | Glass fiber reinforced nylon PA66 | 718cm3 | Normal installation No. 7, select different numbers according to the gauge adjustment. Joint gauge baffle at rail joint |

| WJ8 joint gauge baffle | |||||

| 6 | WJ8 rubber pad | 1 | Natural rubber or synthetic rubber | 140cm3 | Select one of them according to the specific requirements of the line resistance. The composite backing plate is formed by vulcanizing a 1.2 mm thick 1Cr18Ni9Ti stainless steel plate and rubber. Do not use reclaimed rubber |

| WJ8 composite pad | rubber | 110cm3 | |||

| stainless steel | 0.25kg | ||||

| 7 | WJ8 iron rail pad | 1 | QT450-10 | 6.80kg | |

| 8 | WJ8 iron rail pad under the rail pad | 1 | Thermoplastic elastomer (foaming pad) | 540cm3 | The static stiffness of the A-type pad is 30~40 kN/mm, which is suitable for the 250 km/h passenger dedicated line (considering freight transportation); |

| The static stiffness of the B-type pad is 20~26 kN/mm, which is suitable for the 350 km/h passenger dedicated line; the dynamic and static stiffness ratio is not more than 2.0. | |||||

| 9 | Pre-embedded casing D1 | 2 | Glass fiber reinforced nylon PA66 | 115cm3 | The pull-out resistance of the embedded bushing in the sleeper is not less than 60kN. |

| 10 | WJ8 under-rail fine-tuning pad | 1 | Polyethylene injection molding | 25cm3/mm | According to the specific situation |

| 11 | WJ8 iron rail pad down the high pad | 2 | Polyethylene injection molding | 720cm3/10mm | According to the specific situation |

Adapt to Diverse Working Conditions and Ensure Multi-Scenario Application

The surface of gauge baffle plates undergoes anti-corrosion treatments such as black oxide coating, zinc infiltration, and Dacromet coating, enabling them to resist erosion from harsh environments such as humidity, acid and alkali, and adapt to different climatic and line conditions. Their dimensions can be customized to meet the installation needs of various rails ranging from 43 to 75kg/m, and they can also be applied in scenarios such as construction sites and municipal engineering. Moreover, they comply with international and domestic standards such as UIC and GB, ensuring adaptability and reliability.

GNEE supplies a full range of Railway Gauge Baffle Plates, offering material selection and dimension customization services, as well as complete fastener solutions including supporting elastic rail clips and sleeper bolts, to help track engineering achieve long-term stable operation.